Project Overview:

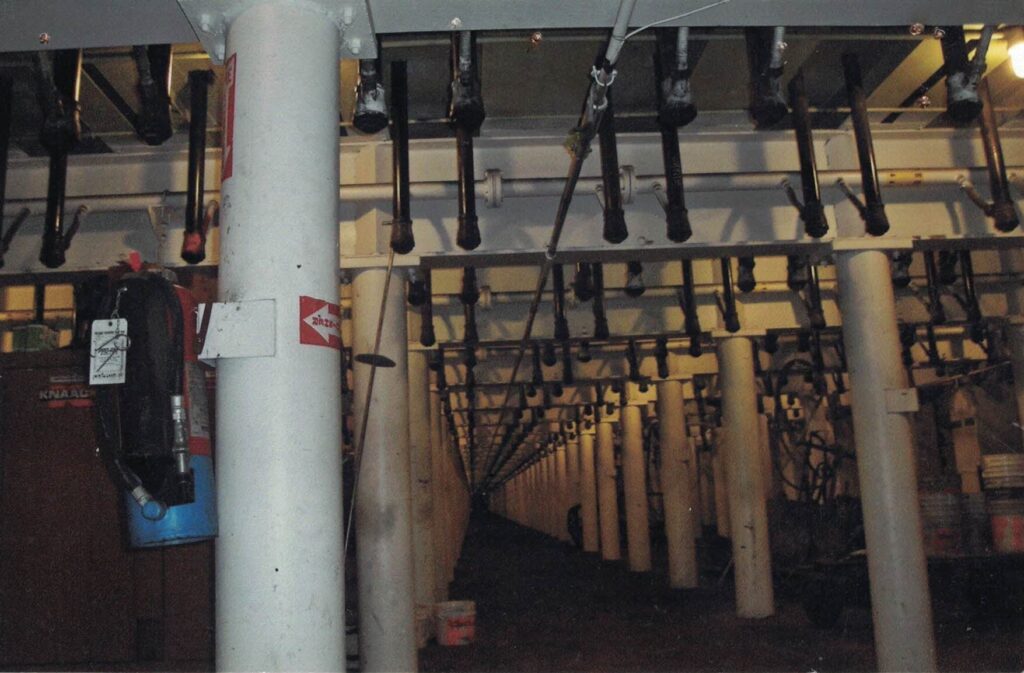

This project is focused on the supply of spare parts for steel mills and coke ovens, particularly involving a critical component – the Gas / Fuel Shut Off Valve.

The Product Having an Issue

The Gas / Fuel Shut Off Valve, a significant part of the infrastructure, was experiencing problems. Its primary function is to intake and purify fuel by filtering out foreign elements. Through the linkage with railroad inner, outer nuts and tubes, these valves regulate fuel flow into the burning chambers.

The Problem They Were Facing With The Product

The client faced a significant issue with the Gas / Fuel Shut Off Valves, as they weren’t efficiently filtering foreign elements and consequently, weren’t delivering purified fuel. This situation not only decreased the heat and efficiency of the burning chambers but also had negative implications for environmental impact.

The Goal The Client Wanted to Achieve

The client’s goal was to address the issue with the Gas / Fuel Shut Off Valve in order to enhance the fuel’s cleanliness, thereby increasing the heat and efficiency of the burning chambers. Simultaneously, the client wanted to mitigate the negative environmental effects caused by the inefficient fuel purification process.

The Solution That Jodat Technologies Co., Inc Came Up With

Jodat Technologies Co., Inc. was brought in to tackle this complex issue. After a meticulous examination of the situation, they engineered an innovative solution involving the redesign of the Gas / Fuel Shut Off Valves. The remodeled valves incorporated advanced filtration methods to eliminate foreign particles more effectively, improving the overall purity of the fuel.

The Impact that this Solution would Have on the Client

The implementation of Jodat Technologies’ solution had a profound impact on the client’s operations. The improved efficiency of the Fuel Gas Valves increased the heat production in the burning chambers, resulting in more efficient steel production. This not only optimized their operational efficiency but also played a significant role in reducing their environmental footprint, aligning with global efforts to combat climate change.

The Time it took to Complete this Solution after Research and Development

After intensive research and development, Jodat Technologies Co., Inc. was able to deliver the final solution within a remarkable time frame. The complete redesign, testing, and implementation of the new Fuel Gas Valves were achieved within the allotted time, ensuring minimum disruption to the client’s operations and swift resolution of their issue.

Why Use Jodat Technologies for Steel Mill and Coke Oven Spare Parts

- Expertise and Innovation: Jodat Technologies Co., Inc. has demonstrated its innovative approach in the field of steel mill and coke oven spare parts, particularly with the Fuel Gas Valves. Their expert team leverages extensive knowledge to craft creative and effective solutions for complex challenges.

- Tailored Solutions: Jodat Technologies doesn’t offer one-size-fits-all solutions. They carefully analyze each client’s specific issues and objectives, resulting in tailored solutions that perfectly fit their needs and enhance operational efficiency.

- Environmental Consciousness: In a world increasingly aware of climate change, Jodat Technologies offers solutions that not only solve operational issues but also reduce environmental impact. Their solution for Fuel Gas Valves, for instance, resulted in a significant reduction in the client’s carbon footprint.

- Efficient Project Execution: Jodat Technologies respects the urgency of operational issues and works diligently to minimize disruptions. They are committed to delivering solutions promptly, as evidenced by their swift turnaround in redesigning, testing, and implementing the Fuel Gas Valves.

- Reliable Support: Jodat Technologies stands by their solutions and offers robust post-implementation support. Clients can rely on them for troubleshooting and maintenance, ensuring the longevity and continued efficiency of their solutions.

- Improving the Bottom Line: By enhancing operational efficiency and reducing environmental impact, Jodat Technologies helps clients optimize their processes and ultimately improve their financial performance. Their solution for Fuel Gas Valves, for instance, resulted in higher heat production in the burning chambers, leading to more efficient steel production and reduced costs.

In conclusion, Jodat Technologies Co., Inc. delivers comprehensive, efficient, and environmentally conscious solutions for steel mill and coke oven spare parts, making them an excellent choice for those seeking improvements in this area. Contact us below to speak to a professional about your project needs.